Materials

Substrate Materials

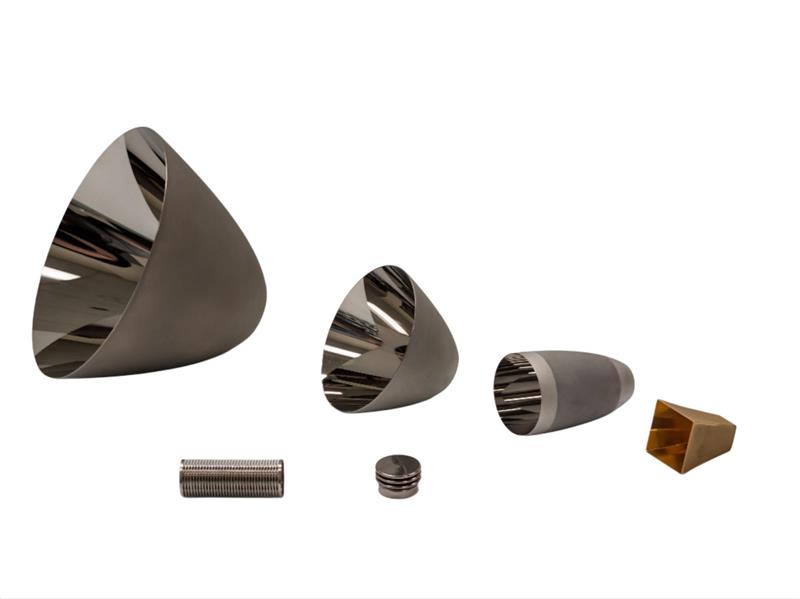

Expand your range of substrates available for fabrication using electroless and electrolytic plating

Component Surfaces brings a wealth of plating Materials Science expertise for fabrication of your products. Combining our knowledge and experience in cleaning, etching, activating and plating technologies, processing is available for a variety of substrate materials including but not limited to:

Metals including alloys and composites of:

- Aluminum

- Copper

- Iron

- Nickel

- Stainless Steel

- Tungsten

- Molybdenum

- Titanium

Metal-Patterned Ceramics

- HTCC and LTCC substrates and assemblies

- Direct Bond Copper and Active Brazed Copper

- Thin-film patterned ceramics & glasses

Non-conductive Materials including varieties of:

- Ceramics

- Plastics (Teflon & other fluoropolymers, ABS, PVC, Ultem, etc.)

- Graphite

request information > quote

We’re ready and waiting

- High-Performance Base Materials

- Thermal Management Materials

- Metallic Coatings

- Plastic Materials

- Ceramic Materials

Non-Conductive Plating Options:

Plating a whole new range of materials.

As the evolution of power electronics in medical, military and industrial applications continues, advancements in processing technologies have created a whole new range of plating options for non-conductive materials.

From plastics and ceramics to glasses and graphites, metal deposits can now be applied to an expanding list of high-performance materials for electrical, thermal and manufacturing improvements.

Explore new surface and plating options with our materials scientists and chemical engineers. Component Surfaces has proven capabilities in a wide variety of materials and applications.