ONE RESOURCE FOR A FULL RANGE OF PLATING SERVICES AND SUPPORT.

From prototype development to efficient production.

Professional Plating Services

Advanced technologies, high-performance materials and proven experience – at your service.

We deliver a full range of professional plating services to satisfy your demanding fabrication requirements.

- Bringing a team of plating and manufacturing experts to support your technology and production demands now and going forward… wherever you need to go with your products.

- Identifying a processing strategy and specifications to meet your product objectives.

- Developing and implementing a process sequence to optimize the performance, quality and efficiency of your parts and their fabrication.

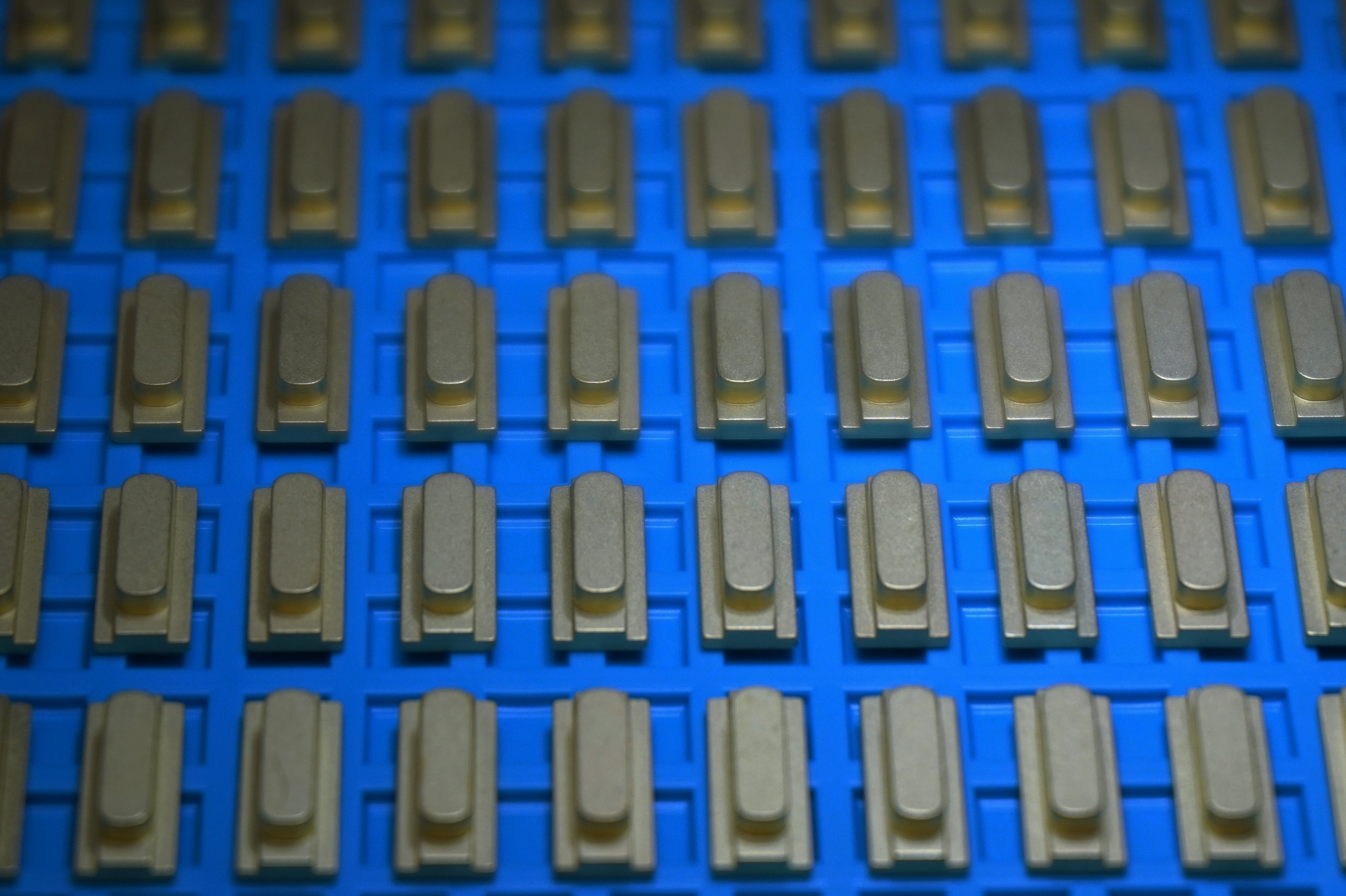

Your parts may be anything from a standard design using traditional metals to a sophisticated assembly utilizing the latest high-performance materials and methods, but your requirements are unique and Component Surfaces is here to bring the necessary resources forward to satisfy them.

request information > quote

We’re ready and waiting

- Product Development

- Production Processing

- Manufacturing

- Pre-Post-Plate

- Optimization

- Inspection

- Testing

- Thickness Measurement

- Packaging

- Certification

PRE-PLATE AND POST-PLATE OPTIMIZATION:

Identifying the correct plating deposit is only the first step in developing an effective plating process.

Identifying the correct plating deposit is only the first step in developing an effective plating process.

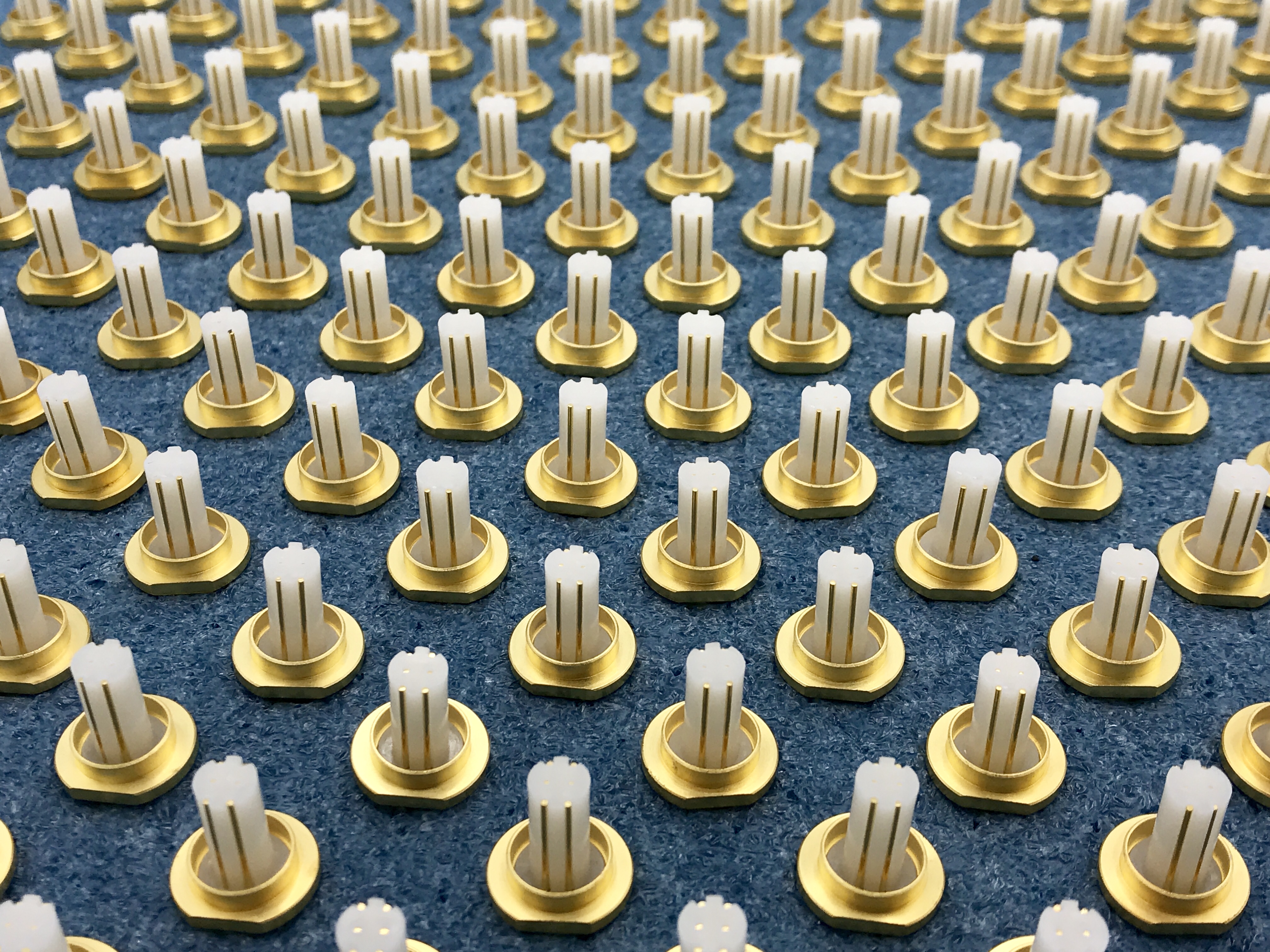

It is also critical to optimize the entire processing sequence including fixture design, cleaning, activation, masking, rinsing and drying steps with primary consideration for your materials, your product configuration and your performance requirements.

Your parts are unique and it is important for your plating processing supplier to recognize this to identify and implement the specific combination of process steps that will work best in your application. Rather than relying on a library of off-the-shelf sequences, we know the value of developing custom plating processes and we have put in the resources and systems to use this custom approach on all orders. Whether it’s electroless gold plating or any of our other metal plating services, we will develop a customized process to fit your needs.

We always consider the variety of issues including for instance, materials compatibility, thickness distribution variation and handling precautions for fragile components. We take care to identify where the critical inspection and measurement points need to be before, during and following processing. These considerations are key to developing an effective and reliable plating processing sequence.